Your Professional Drop-stitch Fabric Supplier

Shanghai DER New Material Co., Ltd is built under EU standard at its production and physical testing methods. production area 60,000 square meter, registered with 2.5 million US dollars. 3 calendars, 1 knife coating machine, 2 hot melt machine and 5 lamination machine, 25 senior engineers and 450 workers make our factory more competitive among the Coated fabric supplies.

Features

- Strong adhesion: By means of strict product formulation, increase the molecular penetration of the coating and the base in the process, make the filme and the coating combined. The molecular bond in the middle of the formation of a one-piece, become a unit, after thousands of times of folding, ensuring that the surface layer and the base cloth will not fall off, tear strength can reach 150N/square meter.

- Flame retardance: GSTARP is manufactured with the highest quality flame retardants, although the highest grades are expensive, which ensure that the product is flame retardant, self-extinguishing when removed from the flame.

- Anti-bacterial and anti-mold: Using special chemical additives, we ensure that all our products have good anti-bacterial and anti-mold effects, do not produce mold in humid and warm environments, maintain the stability of the surface, and do not produce unpleasant odors, prolonging the use of the life of the product.

- Anti algae: GS PVC vinyle is often used in the field of water-contact areas, especially for water storage containers, aquaculture, fish farming, are required to prevent algae, in the manufacturing of the upper and lower bottom molds, GS has specially added additives to prevent algae, so the tarpaulin is algae-proof.

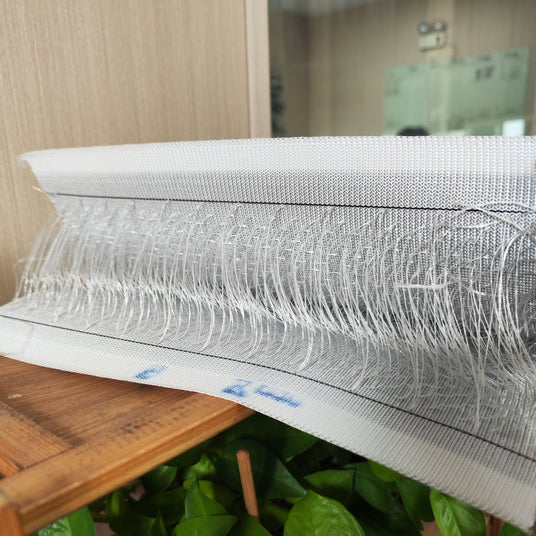

- Double wall fabric with drop stitches in the middle, supply 3D stability region.

- Drop stitches give supports to every spot of the surface, avoiding depressed deformation.

- Favorable adhesion during the welding process.

- Rock-hard rigidity, recommended pressure 20-30 PSI.

Advantages

- High-frequency welded edges achieve 0.05mbar/24hr airtightness, surpassing conventional sealing methods.

- Withstands 1.5MPa (15kg/cm²) pressure without deformation.

- Flexible from -50°C to +70°C (MIL-STD-810G certified).

- UV-resistant for 10,000+ hours (ISO 4892-3) and chemical-proof.

The double wall fabrics are base fabric for coating, such as PVC, TPU and Rubber, the coating fabric can be used to filling with air, gases, gel, liquids, etc.

Material Composition

|

Component |

Specification |

|

Outer Layers |

PVC-coated polyester (500D–2000D) |

|

Drop Stitch Threads |

High-tenacity polyester (0.3–0.8mm thickness per thread) |

|

Adhesive Bonding |

High-frequency welded (RF) or heat-laminated |

|

Total Thickness |

0.8mm–2.5mm (inflated) |

|

Weight |

800–2000 g/m² (varies by thread density) |

Mechanical Properties

|

Property |

Value |

Test Standard |

|

Tensile Strength (Warp/Weft) |

≥ 4000/4000 N/5cm |

ISO 1421 |

|

Tear Resistance |

≥ 100 N (Graves method) |

ISO 4674 |

|

Burst Strength |

≥ 500 kPa |

ASTM D3786 |

|

Peel Strength (Layer Adhesion) |

≥ 50 N/cm |

DIN 53357 |

|

Elongation at Break |

≤ 20% |

ISO 1421 |

Performance Characteristics

|

Feature |

Specification |

|

Air Retention |

≤ 1% pressure loss/24h (at 6–10 PSI) |

|

Waterproofness |

100% (no leakage at 50 kPa hydrostatic pressure) |

|

UV Resistance |

500–1500+ hours (QUV accelerated aging) |

|

Operating Temperature |

-30°C to +70°C |

|

Flammability |

DIN 4102-B1 / NFPA 701 (fire-retardant options available) |

|

Abrasion Resistance |

≥ 10,000 cycles (Martindale test) |

Standard Sizes & Customization

|

Parameter |

Options |

|

Width |

1.5m–3.2m (standard rolls) |

|

Length |

Custom (typically 25m–100m rolls) |

|

Colors |

Clear, White, Gray, Camouflage, Custom Pantone |

|

Surface Finish |

Glossy, Matte, Anti-slip textured |

|

Pressure Rating |

6–15 PSI (higher psi = more rigid) |

Applications & Recommended Configurations

|

Application |

Recommended Thickness |

Pressure (PSI) |

Reinforcement |

|

SUPs (Paddleboards) |

1.2mm–1.5mm |

10–15 PSI |

1000D + 0.6mm threads |

|

Inflatable Boats (RIBs) |

1.5mm–2.0mm |

8–12 PSI |

1500D + 0.8mm threads |

|

Air Floors (Military/Tents) |

2.0mm–2.5mm |

5–8 PSI |

2000D + 1.0mm threads |

|

Inflatable Docks |

1.8mm–2.2mm |

6–10 PSI |

Double-scrim reinforced |

Frequently Asked Questions

Q: Can you provide samples?

Q: Can you provide samples?

A: Yes, of course we'd like to provide you samples to check and test.

Q: What is the samples cost and time?

Q: What is the samples cost and time?

A: Sample cost depends on physical truth; 3-5 days to prepare the samples.

Q: About the samples, what is the cost and time of transportation?

Q: About the samples, what is the cost and time of transportation?

The freight depends on the package weight, size and your exact address including the postal code. ( Sometimes it will generate the additional cost if your exact address is very remote.) Samples express time is about 1 weeks.

Q: What is the mass goods lead time?

Q: What is the mass goods lead time?

A: Usually it is a week. At peak production, it is about 2 weeks.