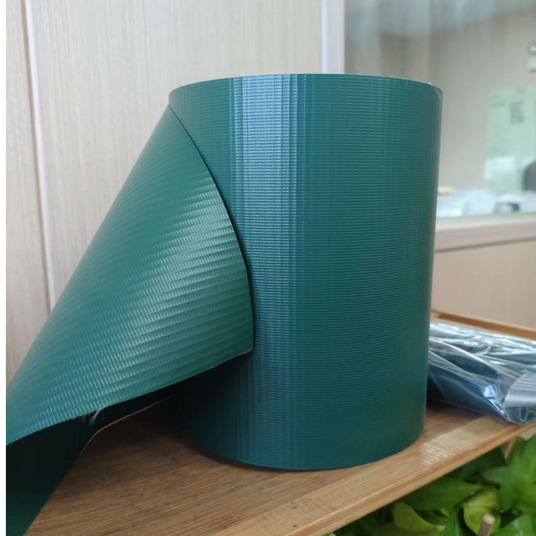

Your Professional Laminated PVC Tarp Supplier

Shanghai DER New Material Co., Ltd is built under EU standard at its production and physical testing methods. production area 60,000 square meter, registered with 2.5 million US dollars. 3 calendars, 1 knife coating machine, 2 hot melt machine and 5 lamination machine, 25 senior engineers and 450 workers make our factory more competitive among the Coated fabric supplies.

Features

- Despite its strength, the fabric remains flexible, allowing the hose to bend and move without cracking or breaking.

- Suitable for use in dynamic applications where the hose is frequently moved or repositioned.

- Resistant to oils, chemicals, and UV radiation, making it suitable for use in harsh mining conditions.

- Designed to handle high-pressure applications without bursting or leaking.

- Available in various thicknesses, sizes, and reinforcement patterns to meet specific mining requirements.

- Colors: Mining ventilation system mainly comes in orange, yellow, grey colors.

- Anti-static character and flame-retardant makes it safe in mining operations.

Advantages

- 100% High Tenacity Polyester Yarns With PVC Coating;

- Laminated Technology & Hot-melt Coating Technology;

- Good Strength, Good Flexibility And Adhesion Strength;

- Outstanding Tearing Strength For Welding;

- Cold Crack Resistance, Anti-Mildew, Anti-Static Treatment, Waterproof;

- Good Color Fastness.

- Special Treatments Adopted To Fit Into Different Industry.

- Special Treatment Available: Flame Retardant; Anti-Static; Anti-cold; Anti-mildew; 3P Etc.

|

Item |

Value |

Unit |

Test method |

|

Basic fabric |

1000D*1000D |

Denier |

|

|

Construction |

12*12 |

Threads/Inch2 |

|

|

Total weight |

650 |

GSM |

|

|

Breaking strength |

L: 3503 |

N/5CM |

DIN53354 |

|

W: 3262 |

|||

|

Tearing strength |

L: 360 |

N/5CM |

DIN53363 |

|

W: 310 |

|||

|

Adhesion |

80 |

N/5CM |

DIN53357 |

|

Color Fastness |

≥7-8 |

Grade |

|

|

Applicable |

-30-70 |

℃ |

|

|

Flame Retardant |

B1 |

| Thickness Range | Description | Applicable scenarios |

|---|---|---|

| 0.30mm - 0.50mm | Lightweight (12-20mil) | Temporary tarpaulin, light truck cover (short-term use) |

| 0.55mm - 0.80mm | Medium-Duty (22-32mil) | Construction fencing, agricultural covering (3-5 year lifespan) |

| 0.85mm - 1.20mm | Heavy-Duty (34-48mil) | Military tents, industrial storage (extreme weather) |

| >1.20mm | Extra Heavy-Duty (50mil+) | Mining dust prevention, special equipment coverage (high abrasion) |

Frequently Asked Questions

Q: What is your delivery time?

Q: What is your delivery time?

A: lt depends on your ordered item and quantity. Normally, we can finish the bulkproducts within 25 days. Urgent order could be arranged in priority.

Q: Can l request samples?

Q: Can l request samples?

A: Yes, of course. Free samples will be sent to you after confirming all details.

Q: Can we visit your company and factory?

Q: Can we visit your company and factory?

A: Sure, and please let us know your visiting schedule then we will arrange factoryvisiting journey in advance.

Q: What's the shipping way?

Q: What's the shipping way?

A: We will provide a good suggestion for delivering the goods according to thevolume of the order and the delivery address. Sea& Air& Train transportation are available.